Quartz Countertops Cleaning For Cafés & Hotels: No-Film Quartz Cleaner SOP

If you source or specify quartz for cafés, hotels, offices, or retail, you’ve probably heard this complaint: “It’s clean… but it still looks dirty.” That’s the frustrating reality of quartz countertops cleaning in commercial spaces—where constant wiping, harsh lighting, and fast-paced teams can turn good intentions into dull, hazy surfaces.

I’ve seen it happen on brand-new installs, too. The slab is perfect, the joinery is sharp, and the finish is exactly what the designer wanted—then the first week of operations hits, and suddenly the surface looks tired.

This article is built like a simple playbook:

First, we diagnose the commercial problems that create film, haze, and “dull quartz” complaints.

Then, we turn that diagnosis into a standardized cleaning system your teams can repeat across shifts and sites—without damaging the surface or creating a residue cycle.

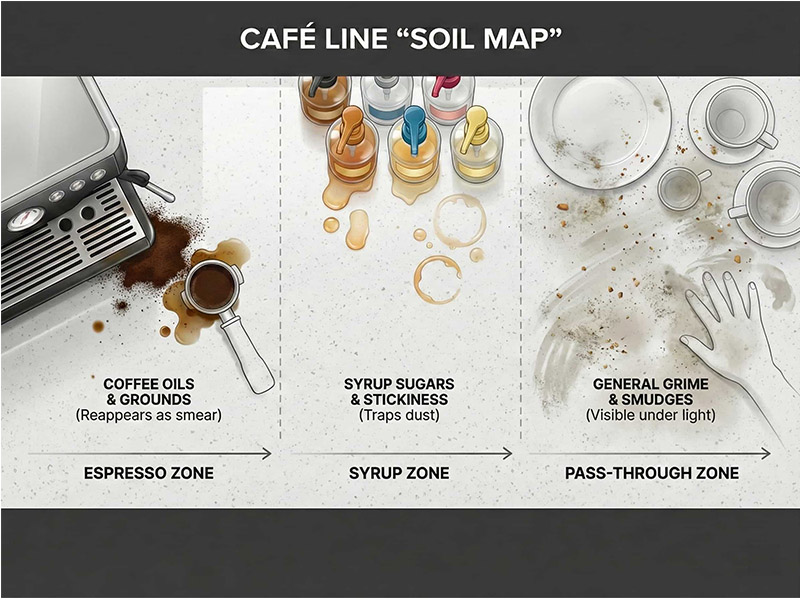

In rush-hour service, countertops become like airport runways: nonstop landings and takeoffs—hands, cups, trays, wipes, sprays—every minute. Film forms fast because the soil mix is not “home kitchen” soil. It’s coffee oils, dairy proteins, syrup sugars, airborne grease, citrus splatter, and even sanitizer drift. These don’t behave like a simple spill you wipe once and forget.

And then there’s the “haze trap”: spray-and-wipe, no rinse, no dry. That routine doesn’t remove everything—it layers tiny leftovers. Under LEDs and pendant lights, the surface starts to look cloudy, streaky, and “smudged,” even when it’s technically sanitized.

In commercial sites, film buildup is extremely common. In homes, it can happen—but usually slower and only in a few zones.

Here’s the core issue: frequent spray-and-wipe leaves behind tiny amounts of residue (surfactants, polymers, fragrances). Add hard water, and minerals like calcium and magnesium land on the surface as moisture evaporates.

One wipe doesn’t ruin a countertop. But hundreds of wipes a day, every day, stacks residue into a thin film that reads as haze and “dull quartz.”

Practical tip: Treat “rinse and dry” like the last step of dishwashing. If you wash a plate and let soap dry on it, it looks cloudy. Quartz is the same—just bigger and under brighter lights.

This is one of the most predictable commercial mistakes: a team sees haze and thinks, “We need more cleaner.” So they double the dose. The surface gets worse.

Soaps and many cleaners lift oils—but they don’t always evaporate clean. If the mix is too strong (or never rinsed), surfactants stay on the surface and attract soil like a slightly sticky magnet. That creates streaking and a “grabby” feel, especially on darker quartz.

Practical tip: More product is not cleaner. In many cases, it’s just more residue.

Honed finishes aren’t automatically “harder to clean,” but they show mistakes faster—especially in commercial settings where wiping is constant.

Polished quartz reflects light evenly, like a calm lake. Honed quartz scatters light more like a sandy beach. When residue dries unevenly, it appears as patchiness, shadowing, or wipe marks. The surface might not be damaged at all—it’s often just uneven residue distribution.

Practical tip: On honed quartz, the final dry microfiber pass matters more than you think. It’s like cleaning eyeglasses—the last wipe is what makes it look clear.

This is the commercial-only headache most teams don’t expect. In cafés and hotel breakfast stations, soils aren’t just “dirt.” They’re a mix of oils, proteins, and sugars. That mix can smear into a thin, invisible layer.

Here’s what happens:

Oils spread thin and don’t rinse easily.

Proteins (think dairy) can haze when they dry.

Sugars become sticky, trapping dust and making the surface feel dirty again.

So even after “cleaning,” the counter can look smeared when the lights hit it.

Practical tip: If the counter looks worse after wiping, stop and switch from “more spray” to “rinse + dry.” You’re likely looking at residue, not damage.

In commercial environments, a reset-clean isn’t a “maybe.” It’s planned maintenance.

Over time, mixed residues (cleaner film + oils + minerals + fine dust) bond into a layer daily cleaning can’t fully remove. The wrong response is abrasives. Abrasives can change sheen—especially on honed finishes—and create a permanent mismatch that looks like wear.

Reset-clean approach (non-abrasive):

Use warm water and a mild, neutral detergent (think pH-neutral).

Work in small sections.

Rinse thoroughly with clean water.

Dry completely with microfiber (no air-dry).

Practical tip: Weekly for high-traffic foodservice, biweekly for moderate traffic, monthly for low-touch reception desks—then adjust.

Now that we’ve named the real causes—film, over-soaping, matte wipe marks, grease/protein soils, and the need for reset cleans—the next step is turning that diagnosis into a repeatable system.

Here’s the key idea: commercial quartz doesn’t fail because it needs “stronger chemicals.” It fails because the wrong products and habits get repeated hundreds of times. So the “best cleaner” is not just a bottle—it’s a spec: the right chemistry plus a method your teams can follow every shift.

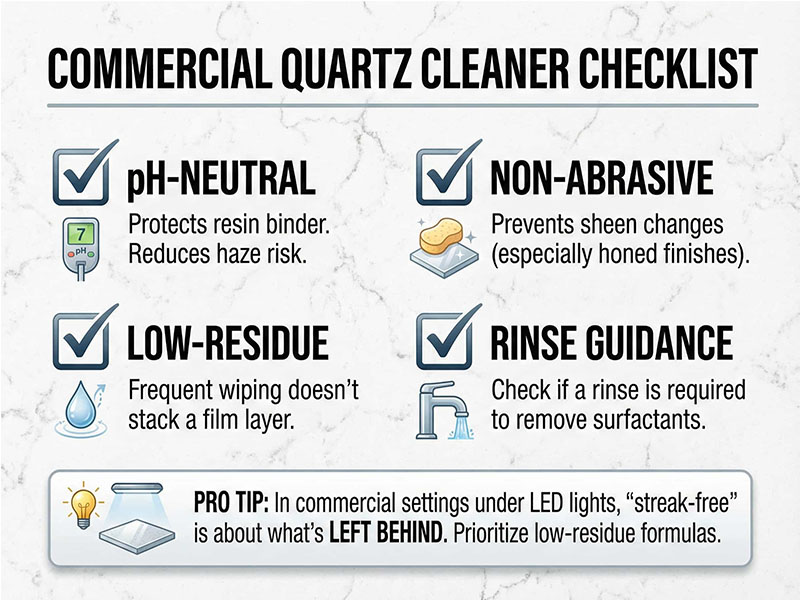

The best starting point is simple: choose a quartz cleaner that is:

pH-neutral to protect the resin binder and reduce haze risk

Non-abrasive to prevent sheen changes (especially on honed finishes)

Low-residue so frequent wiping doesn’t stack a film layer

In a home, people get away with casual choices because cleaning is less frequent and lighting is softer. In a lobby, café, or hotel, every wipe is like adding another “layer of paint” if the cleaner doesn’t rinse clean. Under LED lights, that layer shows up fast.

Practical tip: Don’t buy based on fragrance or “streak-free” marketing claims alone. In commercial quartz, “streak-free” is mostly about what’s left behind after drying.

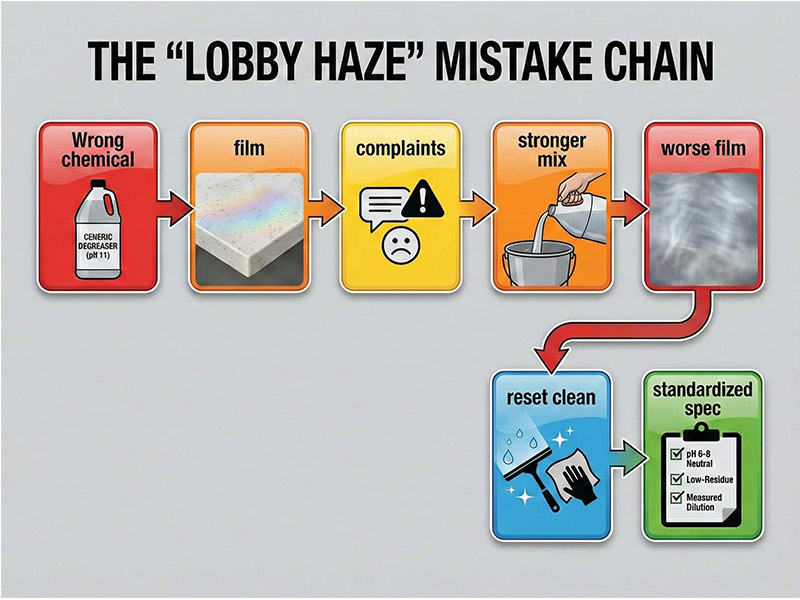

Case Study: The “Lobby Haze” Incident (Procurement & Chemistry)

This is a real-world example of why commercial specs have to be stricter than home use—and why “non-porous” doesn’t mean “chemical-proof.”

Setting: A Class-A Commercial Office Building (San Francisco, CA)

Surface: Black quartz reception desk under bright LED pendant lighting

Issue: Post-renovation visual defect (“greasy,” “smudged,” “cloudy” appearance)

What happened

Right after the renovation, the nightly contractor switched from a stone-safe cleaner to a generic heavy-duty multi-surface degreaser to save money. The logic sounded reasonable on paper: “Quartz is non-porous, so it can handle industrial cleaners.”

Within 10 days, complaints started. The desk looked dirty even immediately after cleaning.

Why it failed

The degreaser was high pH (around 11). It didn’t “burn” the quartz in an obvious way—it left behind a microscopic alkaline film. Under intense LED light, that film read as haze and streaks.

Then the classic commercial mistake kicked in: the crew thought the desk was still dirty, so they doubled the concentration. That added more residue, which made the haze worse. It’s like trying to fix a foggy window by adding more soap instead of rinsing it off.

The fix (and why it worked)

Reset: The facility team performed a deep reset using hot water and a mild, neutral detergent to remove the buildup— by thorough rinsing and drying.

Standardization: The cleaning contract was updated to require a pH-neutral (pH 6–8), low-residue cleaner, plus measured dilution.

Result: The “high-gloss” depth returned immediately. The greasy look disappeared because the film was gone—not because the surface was “repaired.”

Takeaway for buyers and project teams

This wasn’t a quartz quality problem. It was a procurement + training problem. In commercial sites, the wrong cleaner doesn’t just cause one bad day—it creates a repeating cycle that stacks residue until it becomes a visible defect.

The case study above shows why commercial quartz needs structure. The simplest structure that works across sites is a two-step method:

Use a pH-neutral, low-residue cleaner (or mild neutral detergent solution).

Wipe with microfiber.

Rinse with clean water when needed.

Dry with a clean microfiber to prevent water marks and film.

Use an alcohol-based wipe-down only on heavy grease zones (espresso station, syrup zone, pass-through).

Then rinse with water and dry.

Expert insight: Commercial success comes from separating “daily cleaning” from “grease solving.” When crews use one product for everything, they either leave film (too mild) or create haze (too harsh)..

A product can be “safe for quartz” and still fail commercially if it leaves residue. The real test is repetition.

Ask: What happens after 300 wipe cycles?

If the cleaner leaves a micro-layer each time, a café counter can look dull within days—especially on dark quartz under LEDs.

Practical tip: Inspect at night under the same lighting guests see. Daylight hides haze. LEDs reveal it.

For international buyers and construction pros, product vetting should be treated like any other spec—documented, repeatable, and easy to enforce.

Use this procurement filter:

SDS review(refer to section 9 and section 10): Avoid high-alkaline products and harsh solvents unless the quartz manufacturer explicitly approves them.

Dilution controls: Prefer measured dosing (dispensers, pre-diluted formats, or clear ratios).

Training ease: If a process is complicated, it won’t survive shift changes.

Residue behavior: If rinsing is required, make it part of the SOP—not optional.

Before you standardize any cleaner across a portfolio:

Pick an inconspicuous area.

Apply the cleaner exactly as instructed (including dilution).

Let it dwell briefly, then rinse and dry.

Check under strong light after full dry-down.

Repeat for a few days to simulate real use.

This small step prevents expensive mistakes—and protects supplier relationships.

Quartz rarely becomes “dull” overnight. Most of the time, it gets covered—by film, minerals, and mixed soils that build up faster than your teams realize.

If you remember one structure, make it this:

Diagnosis (Section 2): film, soap residue, matte visibility, grease/protein soils, and reset-clean timing.

Solution (Section 3): the right quartz cleaner spec + a two-step system + measured dilution + rinse/dry habits that prevent haze.

If you found this useful, share it with your FM team or cleaning contractor. And if you’ve fought a haze problem before, tell me what caused it on your site—those real-world examples help other buyers avoid the same trap.

Categories

New Blog

© Copyright: 2026 XIAMEN EXCELLENT STONE CO.,LTD. All Rights Reserved.

IPv6 network supported